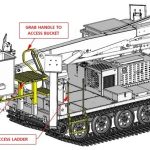

Achiever DLT2-60 65 ft Tracked Aerial

Achiever DLT2-60 65ft Tracked Aerial

The Ultimate Tracked Material Handler. Level off to within 5° on 12° slopes Haul on a 15 Ton Trailer

The Achiever DLT2-60 Tracked Aerial with Jib is designed for stability, simplicity & ease of use for Aerial and Material Handling work. Very low 2.44 psi ground pressure (with 29″ tracks) and high power to weight ratio allows this unit to work where other machines cannot go. Max fording with this unit is up to 36 inches of water. The Achiever DLT2-60 is a top center mount jib & winch configuration. Also available as a double bucket only (24″ x 42″ x 42″) or a single man bucket with jib (24″ x 30″ x 42″) or a double man bucket with jib (24″ x 42″ x 42″).

59″ longer outriggers with 18″ x 20″ feet are standard in the front position and extra-long outriggers (71 in) in the rear give even more lift (20″) for greater stability on hilly terrain and allow deck levelling to within 5 degrees on 12 degree slopes. Extra-long 71″ outriggers are optional for the front position.

Achiever DLT2-60 65 ft Tracked Aerial

General Data

| Max. working height w/basket elevator | 65′ |

| Max. side reach | 39′-2″ |

| Stowed travel height | 9′-4″ (approx.) |

| Extension boom travel | 148″ |

| Main boom travel | -30° to +75° |

| Elevator travel | 22″ |

| Articulating arm travel | -0° to +75° |

| Basket Capacity (Jib not in use) | 550 lbs |

| Basket Capacity (Jib in use) | 400 lbs |

| Max. jib and winch capacity | 1,000 lbs |

| Basket rotation | 180° |

| Base installed weight | 17,700 lbs (approx.) |

Some available options are: Basket Liner, Basket Cover, Tool Trays, Main Boom Fiberglass Insert, Articulating Arm Glass Insert, 12 Volt Emergency Boom Rotation & Lowering, Controls with High Electrical Resistant Components (HERC), Tool Circuit at Basket and / or Base, Hydraulic Basket Leveling at Lower Controls and Hydraulically Extendible Jib. The 134 HP Tier IV Deutz AG electronic engine has cold start options down to -40ºF / -40ºC.

Total completed vehicle weight is approximately 19,000 lbs with ground pressure of approximately 2.44 PSI & stowed height of 112″ allows for transport on a 15 ton trailer behind a line truck. Standard 29″ Rubber tracks allow unloading on pavement. Optional 33″ high profile rubber tracks are available and will provide ground pressure of approximately 2.15 PSI. One man open or closed cab is available. Maximum speed is 7.3 mph.

All Achiever DLT2-60 DU Tracked Aerials are dielectrically tested, Category “C” 46 kVA certified and ready for hot line work when they leave the factory.

The Achiever DLT2-60 DU features a 134 HP electronic Tier 4 engine which combined with the completed unit weight of approximately 19,000 lbs gives a greater power to weight ratio than any other 65 ft tracked aerial. The difference when climbing hills will be noticeable. DEF tanks are equipped.

The standard DLT2-60 DU equipped with block heater and glow plugs will start at up to -4ºF / -20ºC. Addition of either a 120v oil tank heater or a programmable 12v engine coolant heater if no external power is available for the block heater will provide for engine start up to -13ºF / -25ºC. Adding synthetic engine & ISO 22 hydraulic oil and a winter bridge & engine cover will provide for engine start up to -22ºF / -30ºC. An extreme cold package for engine start & operations up to -40ºF / -40ºC is available as well.

UTV has manufactured tracked vehicles since 1995 & tracked digger derricks since 1999. Our customers include many power companies, coops, telecom companies and power line contractors. We service and support every machine we have ever made.

Mobile Lifts, LLC is an Authorized

Dealer-Rental Partner for UTV International

Since 1995 UTV International has been manufacturing Achiever off road tracked vehicles, Hercules digger derricks and Pioneer snow vehicles for the power, utility, telecom, forestry, mining and ski industries. UTV vehicles are designed for power, traction and stability. Simplicity & ease of use features are built in and a wide range of options are available to suit every need. Modern track and suspension design with a low center of gravity combined with a very low ground pressure are the cornerstone of our design philosophy. Continuous design & engineering advancements have resulted in our machines being the most versatile, efficient and cost effective machines available today.